General Disclaimer to Start Off

You shouldn't blow your car up doing this. Don't make map changes unless you know what you are doing. If you do, don't blame me. You typed the number in. You flashed it to the car. That being said, I've never heard of anybody doing damage by logging data. Bottom line, as a blanket statement, I'm not responsible for your car. Just putting it out there.

Introduction

For this installment, I wanted to actually get into something 'physical'. As you progress and learn more about tuning, you'll find the actual electronic tuning part (with the tables and nerdy stuff) is really just a means to control physical/mechanical equipment. If you don't fully understand the mechanical parts behind it... You will chase your tail in excel sheets one way or another. A good example of that is boost control.

Most of the fine details concerning turbochargers I learned from Turbo: Real-World High-Performance Turbocharger Systems by Jay K. Miller. It's a great book - I never realized how little I understood about turbochargers until I read that book.

To start, a turbocharger is one method of supercharging a car - it's a simple concept... Push air into the engine as opposed to pulling it in. Turbocharging tends to be a practical means of doing so - it primarily uses otherwise wasted exhaust heat/energy to compress incoming air for the engine. Other forms of supercharging involve using a mechanical linkage (common supercharger) or chemical injection (nitrous).

Turbocharger Construction:

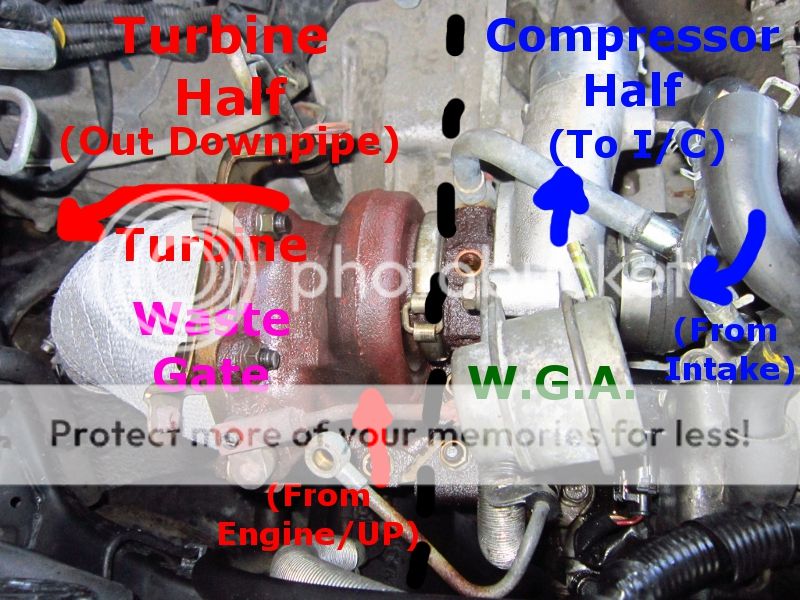

The turbo has three main 'building blocks'. The turbine, the compressor, and the bearings in between. The hard part about the turbo is understanding that both the compressor and turbine must be fit to a given situation. I will go over the Wastegate Actuator (WGA) later in the tread. Just left it there in the pictures for you to note for now.

Thanks to Zax for the turbo pictures in this post. I took them from him... along with some noods which you can't have.

![Image]()

Turbine:

![Image]()

The turbine is one of the two devices you stare at if you take you downpipe off. One being the wastegate (will cover that later), and the little propeller type wheel commonly known as the turbine. As (extremely) hot gases leave the engine, pass into the headers, and through this half of the turbo, the heat and speed of the pulses is transferred into rotational motion. Think of blowing on a pinwheel... then think of using boiling water to spin the pinwheel.

The turbine properties will greatly effect your end outcome. Too small of a turbine will cause excessive exhaust back pressure on the engine (even before your down pipe)... Too big and it will not 'spool' up in a reasonable amount of time. I'd like to emphasis the first point there - regardless of if you want a fast spooling turbo... too small of a turbine will hurt performance - a lot!

Compressor:

![Image]()

On the other end of the shaft from the turbine.. you'll find the compressor. It's important to realize we are now on the other side of the turbo. Instead of this device being between the engine and the down pipe... this one is in between your intake and your engine/intercooler. As expected... the compressor will in fact spin along with the turbine... but it will compress the air in the intake tract of your car and spit the hot gas out to the intercooler.

The compressor properties will also effect your end outcome. An improperly sized compressor will stall/surge, or be out of its efficiency range (big problem - will cover that later). It's important that both the compressor and turbine match the application!

Bearing Housing:

The bearing housing is one of the hot topics now in turbo design. Ball bearing turbos are snatching up the spot light for a good reason. Otherwise, I don't want to dive too far into this. Just know that ball bearing turbos are faster responding and more durable - by a significant margin.

Okay... Now that we understand the two basic halves of the turbo, there are two related topics to take into consideration - variable geometry & boost control.

You shouldn't blow your car up doing this. Don't make map changes unless you know what you are doing. If you do, don't blame me. You typed the number in. You flashed it to the car. That being said, I've never heard of anybody doing damage by logging data. Bottom line, as a blanket statement, I'm not responsible for your car. Just putting it out there.

Introduction

For this installment, I wanted to actually get into something 'physical'. As you progress and learn more about tuning, you'll find the actual electronic tuning part (with the tables and nerdy stuff) is really just a means to control physical/mechanical equipment. If you don't fully understand the mechanical parts behind it... You will chase your tail in excel sheets one way or another. A good example of that is boost control.

Most of the fine details concerning turbochargers I learned from Turbo: Real-World High-Performance Turbocharger Systems by Jay K. Miller. It's a great book - I never realized how little I understood about turbochargers until I read that book.

To start, a turbocharger is one method of supercharging a car - it's a simple concept... Push air into the engine as opposed to pulling it in. Turbocharging tends to be a practical means of doing so - it primarily uses otherwise wasted exhaust heat/energy to compress incoming air for the engine. Other forms of supercharging involve using a mechanical linkage (common supercharger) or chemical injection (nitrous).

Turbocharger Construction:

The turbo has three main 'building blocks'. The turbine, the compressor, and the bearings in between. The hard part about the turbo is understanding that both the compressor and turbine must be fit to a given situation. I will go over the Wastegate Actuator (WGA) later in the tread. Just left it there in the pictures for you to note for now.

Thanks to Zax for the turbo pictures in this post. I took them from him... along with some noods which you can't have.

Turbine:

The turbine is one of the two devices you stare at if you take you downpipe off. One being the wastegate (will cover that later), and the little propeller type wheel commonly known as the turbine. As (extremely) hot gases leave the engine, pass into the headers, and through this half of the turbo, the heat and speed of the pulses is transferred into rotational motion. Think of blowing on a pinwheel... then think of using boiling water to spin the pinwheel.

The turbine properties will greatly effect your end outcome. Too small of a turbine will cause excessive exhaust back pressure on the engine (even before your down pipe)... Too big and it will not 'spool' up in a reasonable amount of time. I'd like to emphasis the first point there - regardless of if you want a fast spooling turbo... too small of a turbine will hurt performance - a lot!

Compressor:

On the other end of the shaft from the turbine.. you'll find the compressor. It's important to realize we are now on the other side of the turbo. Instead of this device being between the engine and the down pipe... this one is in between your intake and your engine/intercooler. As expected... the compressor will in fact spin along with the turbine... but it will compress the air in the intake tract of your car and spit the hot gas out to the intercooler.

The compressor properties will also effect your end outcome. An improperly sized compressor will stall/surge, or be out of its efficiency range (big problem - will cover that later). It's important that both the compressor and turbine match the application!

Bearing Housing:

The bearing housing is one of the hot topics now in turbo design. Ball bearing turbos are snatching up the spot light for a good reason. Otherwise, I don't want to dive too far into this. Just know that ball bearing turbos are faster responding and more durable - by a significant margin.

Okay... Now that we understand the two basic halves of the turbo, there are two related topics to take into consideration - variable geometry & boost control.